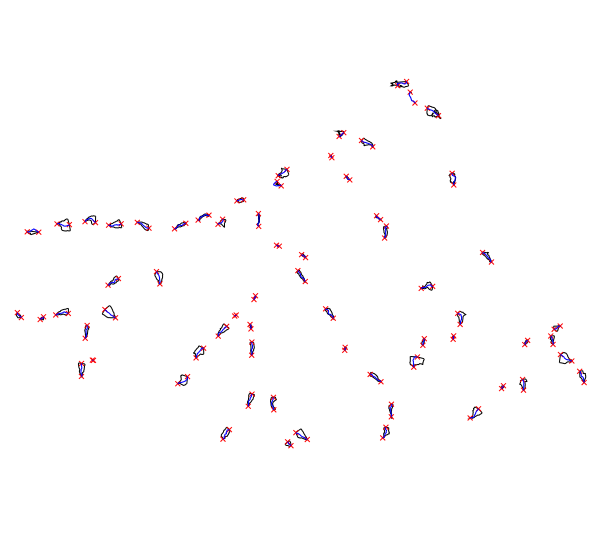

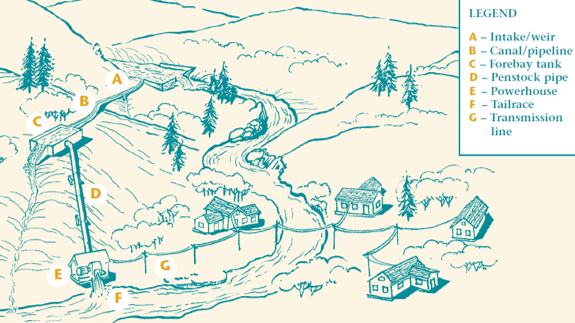

Structure of the plants considered in the module

- in the derivation channelThen, the module chooses the turbine which is the most accurate for each plant. The data of possible turbines of which you have to enter the path into the turbine_folder=string field, are gathered in the folder turbine. For each turbine there is a text file with the ranges of discharge and head required to use it. There is also the efficiency in function of QW/Q_design. The turbine is designed to work at Q_design and QW corresponds to the real discharge which flows in the turbine. As we don't consider the duration curves but only the mean annual discharge, we assume that QW=Q_design.

There are regular losses calculated thanks to Manning's formula: Δhderiv=L*(Q/(ks*A*Rh2/3))2- in the forebay tank

where Rh is the hydraulic radius (m),

A the cross sectional area of flow (m2),

L is the channel length (m),

Q is the discharge (m3/s),

ks the Strickler coefficient (m1/3/s), we consider steel as default parameter, with ks=75 m1/3/s.

There are singular losses caused by the change of section in the forebay tank and the change of direction in the penstock (steep slope).- in the penstock

In any case, singular head losses are expressed like this: Δhsing=K*V2/(2g)

where V is the velocity (m/s),In our case, the singular losses are the sum of the ones for these three phenomena:

g the gravity term (9,81 m/s2),

K is a coefficient determined according to the kind of singularity.

- enlargement at the entrance of the forebay tank: K1=1 and V=1 m/s

- narrowing at the exit of the forebay tank: K2=0.5 and V=4Q/(πD2) m/s

- bend at the beginning of the penstock: K3=(gross head/L)2+2*sin(ASIN(gross head/L)/2)4 and V=4Q/(πD2) m/s

There are regular losses calculated thanks to this formula: Δhpen=(f*8*L*Q2)/(π2*D5*g)

where L is the penstock length (m),

D is the penstock diameter (m),

Q is the discharge (m3/s),

f is the Darcy-Weisbach friction coefficient, which can be determined by Colebrooke formula. We consider steel by default with absolute roughness of ε = 0,015 mm.

In the turbine folder there is already the text file called list with a large choice of turbines available. You have to enter the path of the list file into the turbine_list=string field of the GUI. But the user can also create his own text file that has to have the same structure with a list of the names of the turbines he has selected and wants to be considered.TURBINE ALPHA_C Name of the turbine Value of alpha_c Q_MIN Q_MAX Value of q_min Value of q_max DH_MIN DH_MAX Value of dh_min Value of dh_max QW/Q_design ETA Coordinates of the curve efficiency=f(QW/Q_design)

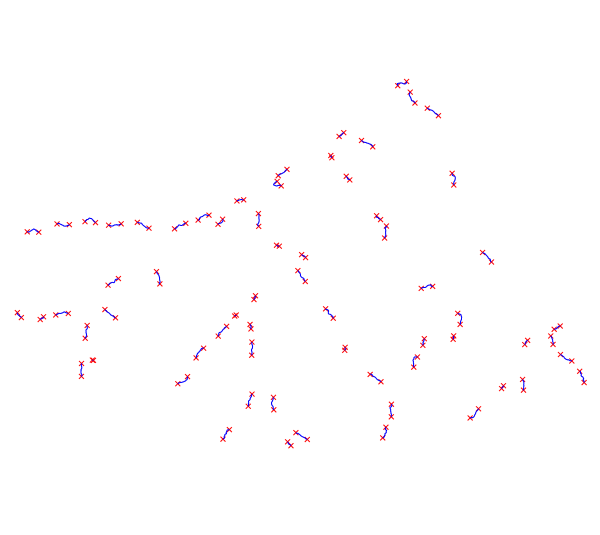

where η is the global efficiency of the plant (turbine, shaft, alternator and transformer),The output map of the module is the one with the structure for each plant, including in the table the data of:

ρ the density of water (1000 kg/m3),

g the gravity term (9,81 m/s2),

Q the discharge (m3/s),

Δhnet the net head, that means the gross head minus head losses

- discharge (m3/s)

- gross head (m)

- kind of the channel: derivation (conduct) or penstock

- side of the river (option0 or option1)

- diameter of the channel (m)

- losses in the channel (m)

Moreover, only in the penstock's line of the structure, there are:

- singular losses (m) in the forebay tank between the derivation channel and the penstock

- the total losses (m) for each structure, which are the sum of the regular losses in the derivation channel and in the penstock and the singular losses in the forebay tank

- net head (m), which is the gross head minus the total losses

- hydraulic power (hyd_power, in kW) which is the power considering the gross head and a global efficiency equal to 1. It corresponds to the theoretical power (the maximum)

- efficiency of the selected turbine (e_turbine)

- kind of the selected turbine (turbine)

- power (kW) which can be exploited considering the technical constrains

- global efficiency (power/hyd_power)

- max_power: yes or no, yes for the side (option1 or option0) which produces the most power

r.green.hydro.technical plant=potentialplants elevation=elevation output_struct=techplants output_plant=segmentplants turbine_folder=/pathtothefileoftheturbine_folder turbine_list=/pathtothefileoftheturbine_list